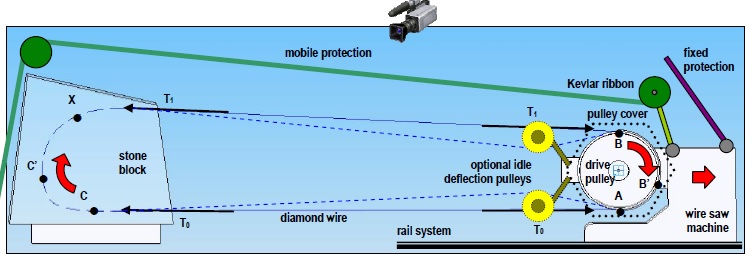

Unfortunately, this new extraction method has also caused a crucial increase of risks for workers. Risks are due to the presence of a diamond wire looped partly around the drive pulley of the wire saw machine and in a kerf in the material to be cut. The wire loop itself, up to tens of meters long, runs at high speed, up to 40 m/s, and presents a risk of contact for workers.

Unfortunately, this new extraction method has also caused a crucial increase of risks for workers. Risks are due to the presence of a diamond wire looped partly around the drive pulley of the wire saw machine and in a kerf in the material to be cut. The wire loop itself, up to tens of meters long, runs at high speed, up to 40 m/s, and presents a risk of contact for workers.

A much higher threat is represented by the wire breakage (Chaplin 1995, Huang & Xu 2006), for the projection of its active elements (diamond beads) and parts (springs and/or spacers) that are closer to the broken ends. In some conditions, they can reach very high speeds, higher than the speed of sound, causing even risk of death, also for workers at tens of meters of distance from the cutting machine.

To reduce risk factors, machine and diamond wire manufacturers from the Italian leading Massa-Carrara stone district have pointed out restricted areas around the machine, and propose the adoption of fixed and mobile protections on the machine and over the wire loop (Figure).

Loading…

Loading…

This work has been sponsored by a Consortium of manufacturers from the same district in order to understand the phenomena occurring immediately after the wire breakage and to assess the effectiveness of current protection measures. Despite the fast development and diffusion of diamond wire cutting, the intrinsic risk of death caused by the ejection of diamond beads in case of wire breakage is still an open problem.

Over 30 experiments have been documented by high-speed imaging and analyzed in two conditions: without protections, to examine the behaviour of a free diamond wire (which has been also simulated by a numerical model) and with various protection equipments, to assess their effectiveness in eliminating all or at least drastically reducing risks for workers.This project, sponsored by Italian Carrara manufacturers, aims to evaluate and improve the safety of diamond wire saw machines. This paper describes the phenomena occurring immediately after wire breakage during squaring operations of marble blocks. The results of a systematic series of full-scale experiments with provoked breakage and of laboratory wire testing are provided.