By Louise Murray

Most mineral resources that are attracting the attention of would-be subsea miners fall into three categories:

Polymetallic nodules

Scattered on the seabed at depths of 3.5 to 6km, these golf ball- to potato-sized nodules can form around a nucleus of fish bones or shark teeth on which minerals have accumulated over millions of years.

Consisting of mostly manganese oxides, they also contain metals such as nickel, cobalt and copper, and were first identified as potentially economically attractive back in the 1960s. They also have a high local impact on seabed life forms, for example, trawling for shellfish. But at much greater depths, in colder waters, biodiversity would be slow to recover.

Seafloor Massive Sulfides (SMS)

These metal-containing deposits are located around mid-ocean ridges where the sea floor is, or was, volcanically active. Mineral-rich superhot water from underlying magma meets cold deep seawater and forms a crust on the seafloor at a depth that is often richer in minerals, particularly copper, than can be found in land deposits. Active ‘hot smoker’ vents with their rich biological diversity, often compared to coral reefs or rainforests, are likely to remain off-limits. However, the seabed contains much larger areas of extinct or inactive zones of SMS, though these are harder to find. Most of the rights to the exploitation of SMS at the mid-Atlantic ridge have already been granted by the International Seabed Authority.

Cobalt-rich ferromanganese crusts

These form by precipitation from seawater on to hard rock surfaces over millions of years, mostly on the flanks of underwater seamounts and extinct volcanoes, often because of subsea volcanic activity in the waters of island states like the Cook Islands. They contain iron, manganese, cobalt, nickel and other minor metals. Rugged terrain may make mining challenging but may result in the least environmental impact.

Loading…

Loading…

The technological developments required to exploit the resources known to exist in the harsh deep-sea environment are, although considerable, perhaps the least of the industry’s worries. After all, it can draw on the experiences of the offshore energy industry, where operations at depths of 3-4km are now almost routine.

The real difficulties begin when one tries to align that with the firm commodity prices, structured regulatory framework and environmental understanding of each area to be mined that are required to take the plunge. And then there is the small matter of the social contract: sufficient agreement that the deep ocean should be exploited at all.

The Canadian-registered, Omani and Russian majority-owned Nautilus Minerals may in late 2019 be the first company to commercially exploit a deposit of ‘seafloor massive sulfides’ (SMS). These are a metal-rich crust containing copper, zinc, gold and silver that lie 1,700m below the surface of the Bismarck Sea, the territorial waters of Papua New Guinea.

The Canadian-registered, Omani and Russian majority-owned Nautilus Minerals may in late 2019 be the first company to commercially exploit a deposit of ‘seafloor massive sulfides’ (SMS). These are a metal-rich crust containing copper, zinc, gold and silver that lie 1,700m below the surface of the Bismarck Sea, the territorial waters of Papua New Guinea.

The world’s first giant deep-sea mining machines were delivered by UK-based Soil Machine Dynamics (SMD) to Nautilus Minerals in Papua New Guinea in 2017. However, none have yet been tested at depth due to contractual problems with completion of the production support vessel being built in China.

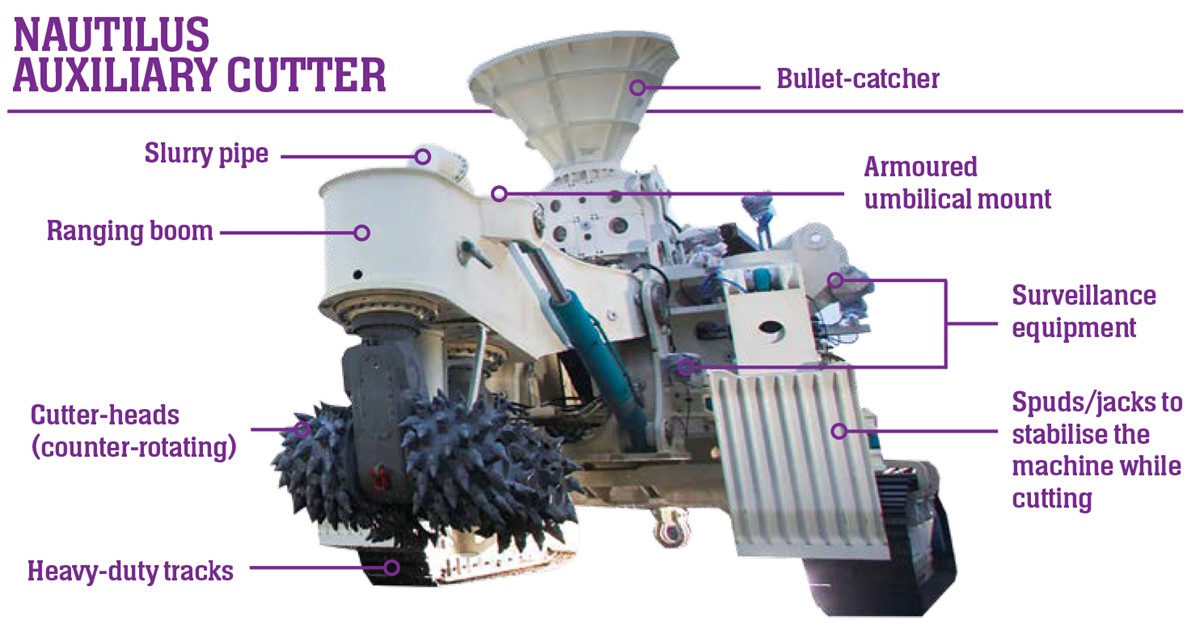

SMD’s Solwara 1 project, which aims to extract SMS deposits from the location, uses three machines that are needed to work the metal-rich SMS crusts in the Solwara 1 field. At these depths, copper is found at concentrations of seven times that of the average land-based mine. The first machine used as part of the extraction is the auxiliary cutter, which creates a level working surface for the subsequent bulk cutter and collector machines.

The bulk cutter is the main production machine and the heaviest deep-sea mining unit ever built, weighing in at over 300 tonnes. “Designing a ship-based launch and recovery system was challenging for something of that size” says Stef Kapusniak, mining business development manager at SMD. “We settled on a cantilever system. The installed power of the cutter head is also bigger than any other rock cutter at 1.2MW. The power is supplied via an umbilical from the vessel.”

In the planned mining technique, the giant bulk cutter grinds up the seafloor with each pass, before the collector sucks up material from the piles made by the bulk cutter, which is then transferred via a riser pipe to the production support vessel on the surface, where it is dewatered. The dewatered ore slurry is transferred to another vessel, which transports it to China for processing.

Each of the mining vehicles is controlled remotely from the ship’s control room via an umbilical. This supplies power to multiple copper cores, as well as communications, data and control commands via fibre-optic cables, which are all wrapped in an armoured casing. The umbilical has a bend restrictor to prevent it from contacting the seabed. Each machine also has an intervention panel that can be accessed by a remotely operated vehicle (ROV), which can help couple and uncouple hoses and tools without the need to return the big machines to the surface and can also help in emergency situations.

An environmental impact statement from the company claims that operations at the mine site will produce minimal particulate plumes – which could potentially smother sea life – on a similar scale to those produced naturally by nearby hydrothermal vents, or ‘hot smokers’.

An additional environmental concern is that once the seawater has been removed from the ore-bearing substrate it must be returned to the ocean, and it too will carry small particles that could form a plume where it is expelled. The concentration of these particles is controlled in the operating licence.

Source: https://eandt.theiet.org